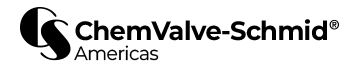

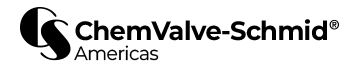

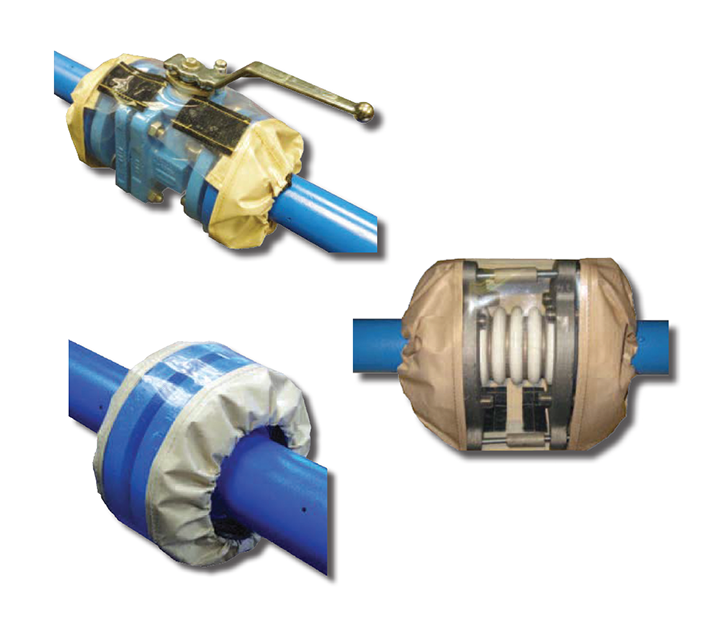

Safety Shields are designed to minimize the impact of a leak or loss of containment from a piping system’s flanged connection, bellows, or valve because of pressure dissipation. In the event of a small leak, the temporary containment provided by the safety shields provides valuable time to detect the leak and take proactive measures before it becomes more serious. The design of the safety shield is to reduce the effect of the system line pressure and route the leak along the piping rather than directly at plant personnel.

Safety Shields can act as a key improvement component of a risk reduction program when used with equipment that is conveying or isolating hazardous materials, high temperature fluids or flammable products. They can assist with achieving the safety requirements of the PED (Pressure Equipment Directive).

The use of safety shields can be throughout a process facility where there is a high level of risk associated with handling corrosive or dangerous substances or specific to piping that is transferring hazardous materials in locations that are above or alongside personnel walkways.

All of the fabric shields come with Velcro fastenings securely sewn onto the shield fabric. This enables one person to wrap the shield around the flange connection and complete the fastening in a short time.

Well retained drawcords give an easy means of closing the shield. Once wrapped around the components the safety shield can be securely tied using the drawcords and a simple reef knot enabling installation by one person in less than a minute.