For more than 30 years we have been a “world leader” in the manufacture of paste extruded PTFE and PFA lined equipment including piping, fittings, columns, bellows, valves, sight glasses, sampling systems and associated equipment.

Our core customer base consists of chemical, chlor- alkali, bromine, fluorine, agricultural-chemical, petrochemical, pharmaceutical, biotechnology, pulp and paper, and metals refining industries.

CRP products are often installed in conjunction with our lined columns as modern chemical processes require multi-purpose function and performance which typically is not available from traditional companies.

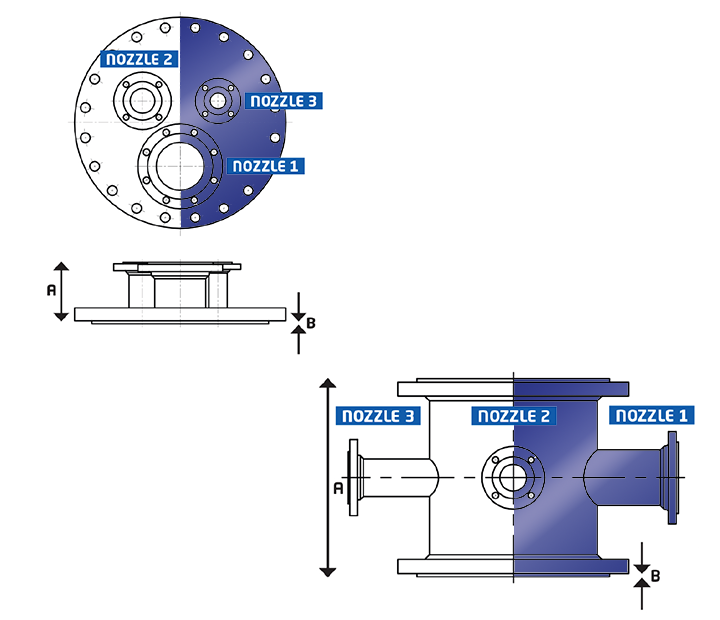

The introduction of our HiPerflon® paste extruded (molecular and mechanically enhanced) PTFE and PFA lined, large diameter columns for critical processes such as strong acids, caustic, bromine, and fluorine at 200° C is a testimonial to our customer focused commitment. Our seamless, 10 mm thick, HiPerflon® linings offer unparalleled, internal corrosion resistance and the absolute lowest rate of permeation, thus significantly enhancing the safety, reliability, and integrity of our customer’s processes and facilities. Our proprietary and unique PFA molded nozzle sections are manufactured in one piece and eliminate the need for PTFE welding and the additional leak paths associated with a multi- piece lined nozzle design.

| Body | NE 10216/7-2 P235 HG TC12/ EN 10216/7-2 P265 GH TC1/2 A PI L5 Grade B |

| Flanges | EN 10222-2 P245GH EN 10028-2 P235GH/P265GH EN 10273 P250GH ASTM A105 |

| Lining | Virgin HiPerFlon® (Paste Extruded PTFE and PFA) |

| PTFE | ASTM D4895 Minimum Tensile Requirements UTS 20,7 MPa Elongation at Break 250% in Both Directions. Specific Gravity in the Range 2,14 - 2,17 Particle Size Average Diameter 500 ± 200μm |

| PFA | ASTM D3307 type Il Minimum Tensile Requirements UTS 26 MPa and 300% Elongation at Break Specific Gravity in the Range 2,12 - 2,17 Melt Flow Rate 1- 3g/10 Mins |

| Options | Stainless Steel, Low Temperature Carbon Steel Anti-static Lining |