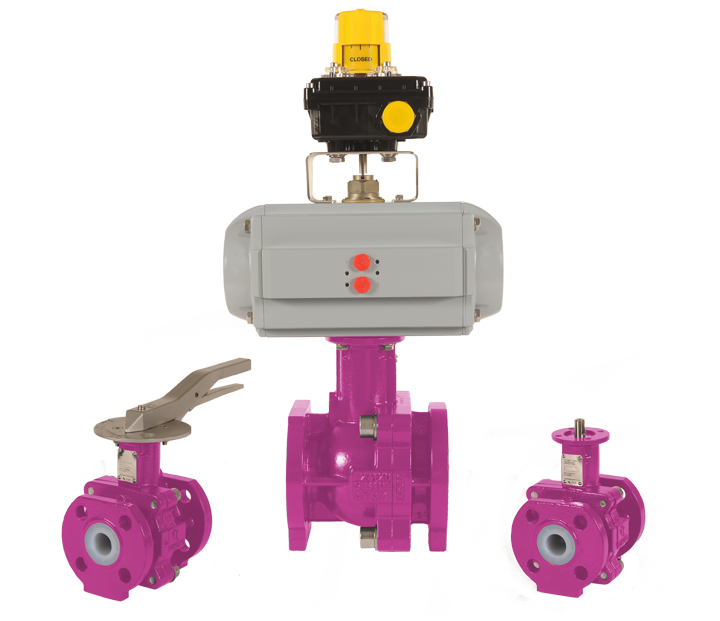

CSB® Series valves are ideally suited for the stringent performance requirements demanded with wet/dry chlorine gas, aqueous hydrochloric acid, and agueous hydrofluoric acid services. Produced from premium virgin grade resins, our thick fluoropolymer linings and ProTef® seat technology features superior resistance to the effects of chemical attack, permeation, absorption, swelling and cold flow thus providing industry with convincing performance. The liner integrity of each valve is tested with 10,000 volts to ensure there are no defects. Valves for chlorine service are thoroughly cleaned and packaged according to our factory procedures and conform to the Chlorine Institute Pamphlet #6 specifications.

CSB® Series valves are designed to offer long-term maintenance-free security against the harmful effects of fugitive emissions. Our innovative, dynamically loaded stem sealing system has established a new standard for safety, reliability and long-term cost of ownership in the lined ball valve market.

| Optional | ||

|---|---|---|

| Body | A-395 Ductile Iron | A-216 WCB & A-351 CF8M |

| Lining | PFA | PVDF |

| Temperature | -40°F to 400°F (PFA) | 0°F to 275°F (PVDF) |

| Pressure Rating | 250 PSIG (A-395 DI) | 285 PSIG (A-216 WCB/A-351 CF8M) |

| Size | 1/2” - 8” | |

| Application | Reliable Isolation & Control of Extremely Hazardous Liquids and Gases | |

| Conforming Standards | ASME B16.5, ASME B16.10, ASME B16.34, API 598, PED 2014/68/EU, ATEX 2014/34/EU | |

| Stem Sealing | Dual Set of Dynamically Loaded PTFE Packing Certified TA Luft VDI 2440 5.2.6.4 and ISO 15848-1 | |

| Process Sealing | Bi-directional, Gas Tested, Bubble Tight per API 598/EN 12266-1-P12 Rate A | |

| External Coating | 3 Component Epoxy Paint | |

| Control Characteristics | Equal Percentage | |

| Connection Type | ASME 150# Flanged | |

| Flow Direction | Bidirectional |