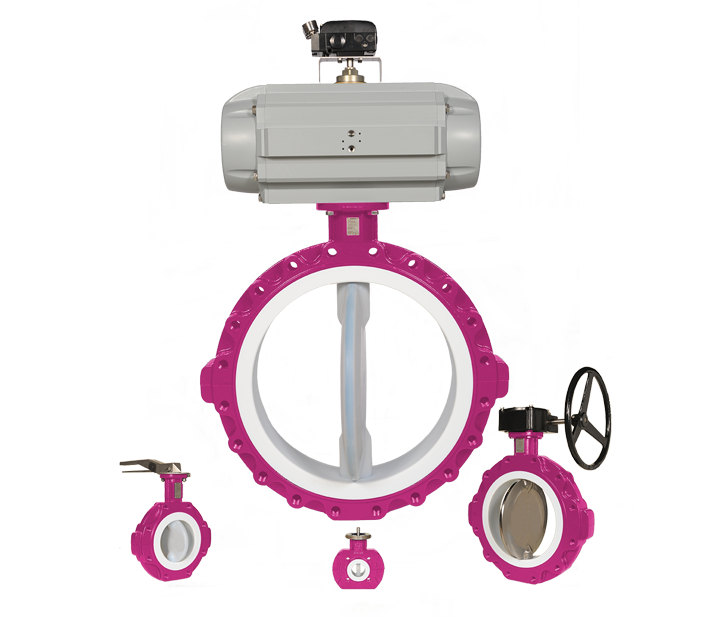

CS® Series high performance lined butterfly valves are ideally suited for the stringent performance requirements demanded with isolating and controlling bromine, wet and dry chlorine gas as well as hydrochloric acid. Valves for these hazardous chemicals are thoroughly cleaned, dried and packaged per our factory procedures and conform to Chlorine Institute Pamphlet 6 requirements. Our environmentally safe, mechanical shaft sealing technology and ProTefTM (Molecular and Mechanically Enhanced) body lining offers industries using these highly regulated chemicals unparalleled performance, permeation resistance and reliability.

CS® Series valves are designed to offer long-term maintenance-free security against the harmful affects of fugitive emissions. Our industry validated, innovative stem sealing system has revolutionized the performance benchmark for lined butterfly valves and has established a new standard for safety, reliability and environmental security.

| Optional | ||

|---|---|---|

| Temperature | -40°F to 450°F (PFA) | 0°F to 275°F (PVDF) |

| Connection Type | ASME 150# Flanged | PN 6, PN 10, PN 16 |

| Lining | ProTef® | UHMPE, PVDF |

| Body | A-395 Ductile Iron | 316 Stainless Steel |

| Size | 1” - 48” | |

| Max Pressure | 250 PSI | |

| Application | Reliable Isolation & Control of Extremely Hazardous Liquids & Gases | |

| Conforming Standards | API 609, API 598, ASME B16.5, ASME B16.34/42, MSS SP-25 & MSS SP-68 | |

| Stem Sealing | Dynamically Loaded Mechanical Shaft Sealing System | |

| Process Sealing | Gas Tested, Bubble Tight per API 598/EN 12266-1-P12 Leakage Rate A | |

| External Coating | 3 Component Epoxy Paint | |

| Flow Direction | Bidirectional | |

| Control Characteristics | Equal Percentage |